charpy impact test science direct|charpy impact test explained : commercial The Charpy impact toughness of aluminum alloys is reduced via introduction of the . 14 de jan. de 2024 · O progresso incessante da tecnologia de celulares nos trouxe uma série de vantagens, mas, ao mesmo tempo, colocou em xeque a durabilidade das .

{plog:ftitle_list}

29 de jan. de 2022 · By Dim Pixel Animations on Jan 31, 2022 16:27 * If there's any DeviantArt content you would like to see re-uploaded here, feel free to leave a comment and I'll add it as soon as I can! I'll try to upload .

testing spider injectors 5psi drop

charpy impact testing procedure

The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This .Mechanical testing of welds. Philippa Moore, Geoff Booth, in The Welding .The Charpy impact toughness of aluminum alloys is reduced via introduction of the .

charpy impact testing methods

The widely used Charpy impact test is a standard way to assess toughness .

The widely used Charpy impact test is a standard way to assess toughness quantitatively in notched specimens. In this test a standard bar specimen, with a square cross section and a V . A comparative experimental and FEM study has been carried out, in order to investigate dynamic and constraint aspects of the Charpy test. Standard V-notch Charpy .

Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTMCharpy Impact Testing. Chapter. pp 151–162. Cite this chapter. Download book PDF. Ghatu Subhash & Shannon Ridgeway. Part of the book series: Synthesis / SEM Lectures on .

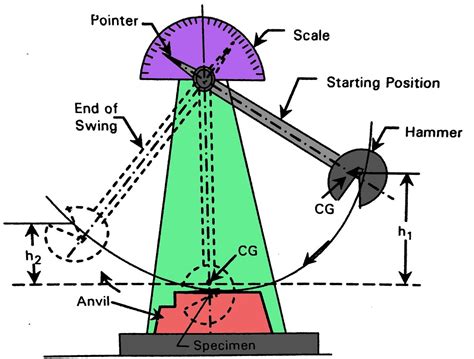

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a .The Charpy impact test, also known as the Charpy V-notch impact test, measures the energy a material absorbs when it fractures under an impact load. A pendulum in a Charpy impact test . This paper investigates using the Charpy impact test as a certification test for a production batch. First, the best conditions for surface finishing and then the Charpy impact . A Charpy test determines the impact toughness of metal samples by striking them with a swinging mass. The traditional test method requires measuring the difference between the height of the striker before and after .

Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its . A novel method for measuring the dynamic fracture toughness, K Id, using a Hopkinson pressure bar loaded instrumented Charpy impact test is presented in this paper.The stress intensity factor dynamic response curve (K I (t)−t) for a fatigue-precracked Charpy specimen is evaluated by means of an approximate formula.The onset time of crack . INTRODUCTION The worthiness of the Charpy impact test would be extended by a procedure that allows to interpret Charpy test results in terms of fracture toughness. Until recently only empirical approaches were available. A non-empirical procedure for the exploitation of the Charpy V-notch test is promised by the 'local' approach. Impact test. The impact tests in this paper are Charpy impact tests performed at room temperature, and the samples are all unnotched. The samples divided into 4 groups according to the volume fractions of 0%, 10%, 20%, and 30% were tested to measure the impact toughness of the composites at room temperature.

Charpy impact test has been simulated using J-C constitutive and failure models with the determined parameters. Reasonable agreements between the simulation and experimental results have been achieved. On this basis, the effects of the pendulum velocity, specimen width and striker radius on Charpy impact test results are studied. Search ScienceDirect. Materials Today: Proceedings. Volume 46, Part 7, 2021, Pages 2414-2420. Estimation of fracture toughness (K IC) using Charpy impact test for Al6061T6 and Al7075T6 alloys subjected to corrosion. Author links open overlay panel S. Sunil Kumar a b, Neelakantha V. Londe b, K. Dilip Kumar c, Mohammed Ibrahim Kittur d. What Is the Charpy Impact Test? The Charpy Impact Test, also known as a V-notch test, evaluates a material’s impact strength by measuring the energy required to fracture a standardized sample with a machined V-notch. Using a released pendulum, the test calculates energy absorption based on the pendulum’s height before and after passing . The impact energy needed to fracture an unnotched Charpy specimen in a BFCM test can be two orders of magnitude higher than the typical impact energy of a Charpy V-notch specimen. To predict material failure, a phenomenological, stress triaxiality dependent fracture initiation criterion and a fracture evolution law in the form of strain .

Charpy impact test has been simulated using J-C constitutive and failure models with the determined parameters. Reasonable agreements between the simulation and experimental results have been achieved. On this basis, the effects of the pendulum velocity, specimen width and striker radius on Charpy impact test results are studied.

The irradiation test (about 10 × 10 19 cm − 2, E > 1 MeV) in research reactor of the pressure vessel material was carried out, and the charpy impact test has been carried out before and after the neutron irradiation. Analysis of the impact energy and the fracture morphology has been done to estimate the embrittlement due to neutron .Impact testing most commonly consists of Charpy and Izod specimen configurations. The Izod impact test differs from Charpy impact test in the way that the notch is positioned facing the striker. Thus in the Charpy test, the test piece is held horizontally between two vertical bars, but in the Izod test, the specimen stands erect, like a fence post.

1. INTRODUCTION INSTRUMENTED Charpy impact test is useful to estimate toughness of a material. However, in the present state of things in which the fracture mechanics approach has spread widely, it is important to apply the instrumented Charpy test from the above fracture mechanics viewpoint.Mechanical testing of welds. Philippa Moore, Geoff Booth, in The Welding Engineer s Guide to Fracture and Fatigue, 2015. 9.5 Charpy testing. The Charpy test measures the energy absorbed when a notched bar of material is struck with a fixed-weight pendulum swung from a given height. The absorbed energy (in joules) is also referred to as the impact toughness of the material. Charpy impact test and three-point bending test were used in order to obtained the impact response and flexural behavior of different laminates. An experimental test series was carried out to determine impact energy absorption, flexural strength and stiffness and failure mechanisms of composite laminates made from M 21 E / IMA , an . The results of this study have shown that the Charpy impact test can produce similar failure modes as the short-beam shear test, while requiring simpler equipment and less testing time. The general information provided by both of these tests is comparable, meaning the Charpy impact test can be reliably used for qualitative comparisons or .

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material's notch toughness.It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and . KEY WORDS Charpy V-notch specimen, instrumented Charpy test, fracture toughness, general yielding, structural integrity Instrumented Charpy Test Review and Application to Structural Integrity Watanabc measured load-time response as early as 1929 [6] by applying stain gages on the anvils of the Charpy machine.

charpy impact test sample

Conventional instrumented Charpy testing is performed using a striker edge instrumented with strain gauges. The striker edge is normally designed according to the ISO 148-1 [2] standard or ASTM E23 [3].The strain gauges may be placed on the striker at various locations which have been found to result in significant differences in the impact energies derived from .

charpy impact test formula

Read the latest chapters of European Structural Integrity Society at ScienceDirect.com, Elsevier’s leading platform of peer-reviewed scholarly literature. Skip to main content . select article On the utilization of the instrumented Charpy impact test for characterizing the flow and fracture behavior of reactor pressure vessel steels. . Download: Download high-res image (100KB) Download: Download full-size image Figure 1. Charpy impact toughness vs. temperature for pure Sn and the BMG Vitreloy 1 compared with data obtained from Refs. [9], [10].The plot shows that the compact impact setup used in this work recreates the correct DTBT temperature in Sn and reproduces the shape of . In recent decades, a lot of research has been conducted on the relationship between Charpy impact test and fracture toughness test [3]. Sheikh and Arif [4] concluded that in the upper shelf region of the ductile–brittle transition curve, despite the fact that for materials with different strength the specific empirical formula can be diverse, but they all have the form .

The Charpy impact test was introduced in the late 1940s as a standard material test for welded steel construction, as a result of studies carried out on ships which suffered unstable brittle fractures. The Charpy impact test is a commercial quality control test for steels and other alloys used in the construction of metallic structures [14–18].

testing the five second rule on dropped food

ScienceDirect Available online at www.sciencedirect.com Procedia Structural Integrity 42 (2022) 1475–1482 2452-3216 © 2022 The Authors. Published by Elsevier B.V. . Charpy impact test 1. Introduction Fracture is defined as the separation of a material into two or more parts under the influence of stress. Fracture in majority of the . The tensile and Charpy impact properties of Ti5111 alloy under different temperatures: (a) engineering stress-strain curves, (b) the variations of R p0.2 and EL on the test temperature, (c) the impact load-deflection curves, and (d) the variation of impact absorbed energy on the test temperature. Nomenclature. Symbol. Meaning, Unit. CVN. Charpy V notch, — CT. Compact tension, — 3 PB. Three point bend, — K. Stress intensity factor, MPa

This paper provides a detailed analysis of the Charpy impact trace to show the valuable information that can be obtained from the Charpy impact test beside the usual data related to energy, in particular: .9 the flow properties; .9 the microcleavage fracture stress; .9 the crack arrest performance; .9 the characteristic transition temperatures . This work presents, for the first time, and estimation of fracture toughness K IC correlations from Charpy V-notch (CVN) impact test data extracted from T-welded connections repaired with rectangular grinding and filled by wet welding. To obtain K IC values, equations based on the yield stress (σ YS) of the wet welding beads were used.The estimated K IC data . All these elements contribute to the differences between the Charpy impact test results and quasi-static fracture toughness data, in particular the tearing resistance responsible for the ductile crack extension occurring in the Charpy V-notch impact specimen in comparison to a plane strain 20%-side-grooved fracture toughness specimen.

testing the needle drop

CSL Plasma rewards website. Login to CSL Plasma. Phone Number. Donor ID / Email +1. Forgot Password? LOGIN. No account yet? Register .

charpy impact test science direct|charpy impact test explained